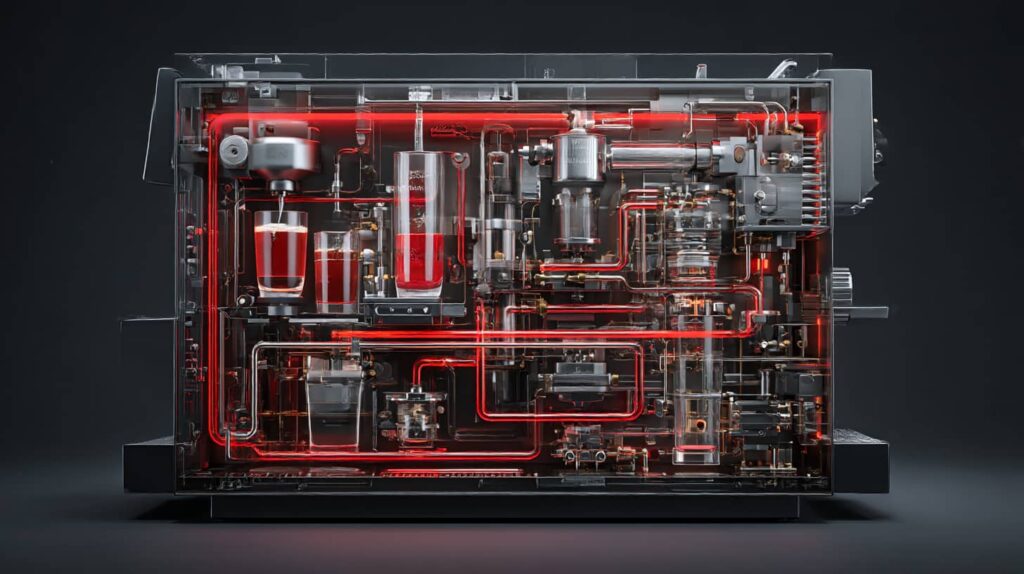

Press the button. Four seconds. The perfect mojito. For guests it's magic, for engineers it's precise science. But what actually happens in those four seconds inside a fully automated cocktail machine? Time for a journey into the heart of technology.

Welcome to the invisible universe of perfect cocktails.

Second 0,1: The command is understood

Touch screen registers "Mojito". The microprocessor analyses the request in milliseconds: Which ingredients? In what order? At what temperature? What quantity?

The invisible orchestra begins:

- CPU calculates 47 different parameters

- Sensors report current fill levels of all tanks

- Temperature modules start cooling circuits

- Printing systems activate themselves for optimum flow

One developer explains: "More data processing happens in these 100 milliseconds than in a 90s computer per minute."

Second 0.5: Logistics awakens

Precision pumps start their choreography:

Pump 1 activates for white rum. Not somehow, but with mathematical precision. 40.0 millilitres - not 39.7 or 40.3. The system measures the flow rate 200 times per second and corrects microscopic deviations.

Parallel to this: Lime juice pump calibrates itself to exactly 15.0ml. The viscosity of lime juice fluctuates by 0.3% depending on the temperature. The system compensates automatically.

Second 1,2: Temperature management

The cooling circuit shows its ingenuity:

Crushed ice doesn't just fall into the glass - it is portioned. Each ice cube is tempered to -2.1°C. Too cold makes the cocktail watery, too warm dilutes the flavour.

A thermodynamics expert from Munich: "These machines master refrigeration technology better than some industrial systems. This is precision engineering at the highest level."

Second 2.1: Chemistry in action

This is where it gets scientific:

Sugar syrup is not just added - it is mixed with rum before acid is added. Why? Chemistry. The order influences the flavour combination between sweet and sour.

The mixing ratio takes place in three phases:

- Alcohol and sweetness combine

- Acid is slowly integrated

- Carbon dioxide is added last

A food chemist: "People mix intuitively. Machines mix according to molecular rules. You can taste the result immediately."

Second 3.0: The garniture precision

Not all mint is the same:

The machine "knows" that mint leaves are different sizes. Sensors measure the volume and dose accordingly. Large leaves: fewer pieces. Small leaves: more pieces. Always the same flavour volume.

Soda integration is pressure-controlled:

- Carbon dioxide level is measured

- Flow velocity adjusted

- Foam formation prevented

Second 3.8: Quality control in real time

The last milliseconds belong to perfection:

Optical sensors check the result. Is the colour correct? Is the fill level correct? Is the layer distribution optimal?

If there are deviations, the system stops and corrects automatically. A faulty cocktail never leaves the machine.

The invisible heroes:

- pH sensors measure acid balance

- Viscosity meters check consistency

- Flavour sensors validate flavour profile

- Temperature scanners check serving temperature

What people cannot do

Why is machine precision superior?

A human bartender estimates quantities visually. Deviation: 15-30%. A cocktail machine measures electronically. Deviation: 0.1%.

A person loses concentration after eight hours. The machine works with identical precision after 8,000 cocktails.

Speed without loss of quality:

- Human bartender: 90 seconds per mojito

- Cocktail machine: 4 seconds with greater precision

The software behind it

What controls this precision?

Modern cocktail machines use the same software architecture as industrial robots. Real-time operating systems with nanosecond response times.

Machine learning in action: The machine learns from every cocktail. After 1,000 mojitos, it automatically optimises timing and dosage based on guest feedback and sales data.

An AI developer: "These systems get smarter with every drink. After a year, they mix better than on the first day."

Maintenance: self-healing on a small scale

What happens at night when nobody is looking?

Automatic self-cleaning cycles start at 3:00 am. Every pipe is flushed, every sensor calibrated, every tank cleaned. The machine heals itself.

Predictive maintenance: Sensors recognise wear before it occurs. The system automatically orders spare parts and plans maintenance windows.

The conclusion of the four seconds

In four seconds, 47 calculation processes, 23 quality controls and 156 sensor measurements take place. The result: a cocktail that tastes exactly as planned.

Every cocktail is a small miracle of technology - packed into four seconds of pure perfection.

The machine is not just a machine. It is a laboratory that produces cocktails by chance.